IR inspection is a game-changer

The long-term energy performance and failure-free operation of a photovoltaic (PV) asset depends on the combined performance of PV modules, inverters and medium voltage transformers organised in multiple power blocks.

During operation, PV modules may develop defects that require repair or replacement. Defects result in lower energy production and sometimes cause safety issues. Infrared (IR) imaging can detect a great variety of failures, from hot-spots to mismatch losses to installation failures, without affecting normal operation.

The IR inspection of PV plants has evolved quickly. Walkabouts with handheld IR cameras have been replaced with fly-overs with drones equipped with high-resolution IR cameras. Digital twins of PV plants can now be created quickly using workflows that integrate, process, and quality-control the IR images generated in drone inspections. Cost-effective plant snapshots can be established during construction, commissioning and operation, to create status and performance sequences supporting asset optimisation and handovers across the lifecycle.

Periodical IR inspections are an emerging alternative to investment in string-level monitoring SCADA systems. Both approaches look at PV performance and in that sense they have an equivalent objective. With IR survey plus comparative energy performance you can address evolution of soiling and plant performance at the same time. As IR surveys become faster and cheaper to run and process they will become the standard option. In turn, this may lead to plant simplification decisions, lower relative investment in and more actual investment in energy generation.

IR inspection of the Pelicano PV

Chile is a fast-growing PV market with some 3.5 GW of installed capacity and an additional 2.5GW capacity projected. The ecosystem of local support services is growing accordingly with costs being more competitive.

Actis Long Life Infrastructure Fund acquired the Pelícano PV asset in December 2017, after the plant commissioning. Pelicano is a 111MWdc (105MWac) plant located in the Atacama Desert (Chile), composed of 59 power blocks and 25,554 strings of 10 high-performance (435W) monocrystalline modules each. Module capacity degrades at 0.25%/year according to the manufacturer. The plant has been performing in line with projections.

At Pelícano, the SCADA system acquires the power data at the inverters and not at the string-level. The plant is an ideal candidate for inspection as the IR will complement the SCADA data.

The aerial inspection of infrastructure using drones and fixed wing aircraft is an established service in the mining, energy, and real estate sectors, with different suppliers available. Pelicano chose a supplier with local PV inspection experience that is associated with a survey processor with global footprint.

The key ´sell´ points of the selected supplier were:

- Availability to shoot the survey with limited contact with site team during the COVID-19 pandemic;

- The deep knowledge of defect interpretation using a combination of artificial intelligence algorithms and expert interpretation;

- The possibility of creating a digital twin with multiple snapshots that are matched module by module in time;

- The possibility of creating O&M workflows to address repairs and then register the repair in the system for future reference; and

- The price (23 k$ all-in).

Survey results and O&M actions

The drone pilot was on site at the end of May 2020 and the final ´digital twin´ report was delivered in one month on a fast turnaround. The O&M and Asset Management teams were granted access and trained on the platform.

All PV strings were operational at Pelícano. This was a first for the 800MW inspected so far in Chile by the drone surveyor. The energy losses associated with the detected anomalies corresponded to 0.1% of total plant generation, which is again a very favourable result.

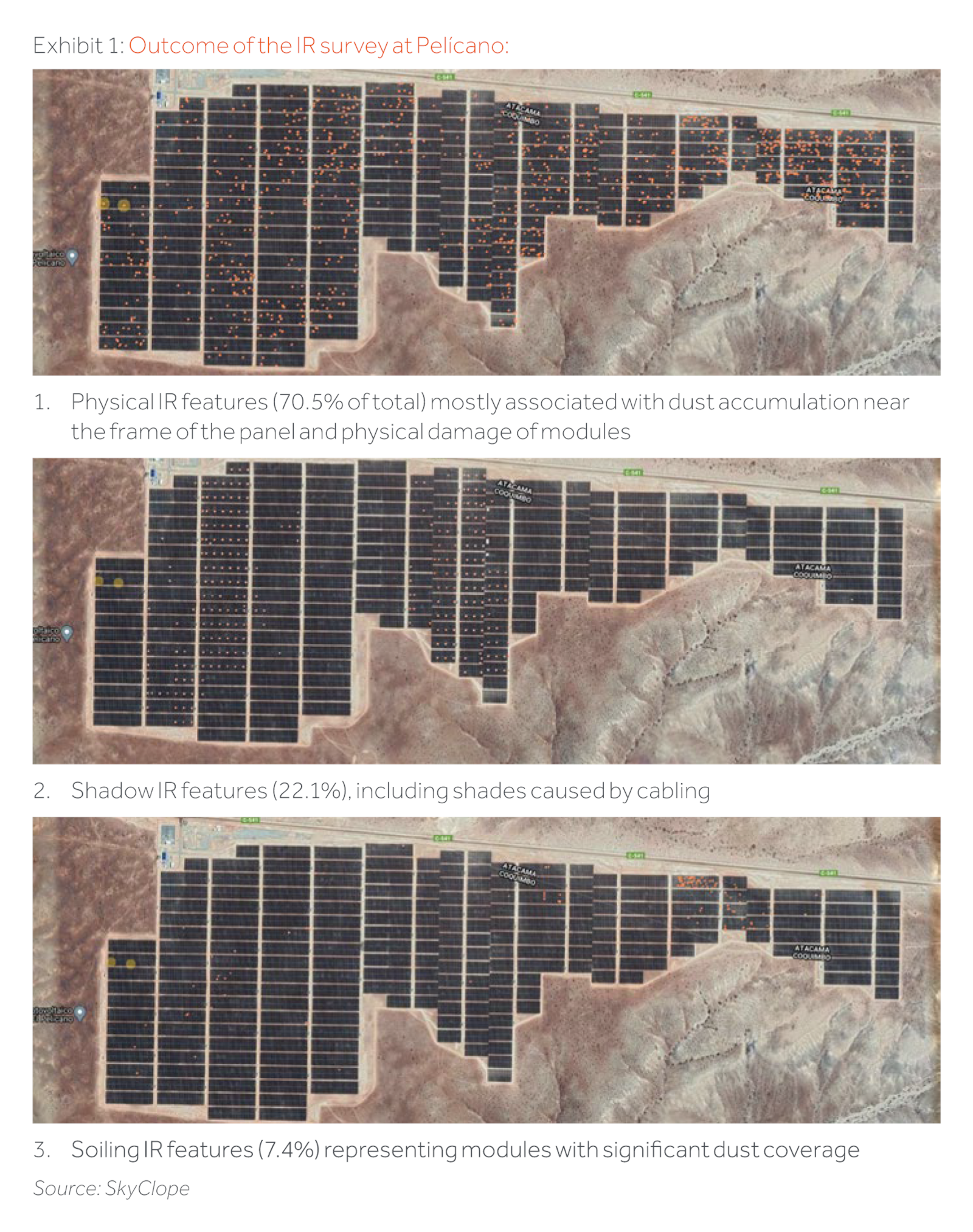

The survey identified 1,878 thermal anomalies for the 255,540 modules at the plant, which is a very low value. The IR was able to distinguish between Physical anomalies in this case 70.5% of the thermal losses (issues related to module/cell damage), Shadowing anomalies with 22.1% (shadows from cables and other features) and Soiling anomalies with 7.4% (in a plant area that was a candidate for washing at the time).

The O&M contractor analysed the results and incorporated actions in the maintenance schedule. No disconnected cables were found and all strings were operational which was a first for plants in Chile. The execution of remedial actions identified three damaged modules in the field with many of the physical features reclassified as soil spot accumulations, located close to the module frame and 6 modules were replaced.

Lessons learned and value improvement

The outcome of the IR survey was very favourable for El Pelicano asset. It provided the necessary certainty on the current plant operational status, with a limited number of issues identified at the module-level affecting the energy output of the plant. The IR survey represents an efficient option to deliver an operational snapshot.

Pelicano had considered retrofitting the plant with string-level monitoring as a value improvement option with a capex estimate of $400k. The IR survey supports a decision to cancel this option.

The IR survey will serve as a baseline to monitor the evolution of the plant status. As the number of actual features was limited and the plant performance remains solid, the next survey is now deferred for late 2021 or early 2022.

The learnings will be transferred to other PV assets of the Energy and ALLIF portfolios, including surveys during commissioning and due diligence processes.