What is happening

From 2016 to 2018, China eliminated 150 million tons of steel manufacturing capacity and 20GW of coal-fired power. Renewable energy played a central role in reducing China’s reliance on fossil fuels, in particular coal.

China has become the world’s largest renewable energy producer by a wide margin, with a total capacity of 728 GW at the end of 2018, more than double that of the United States.

China also leads in the adoption of plug-in electric vehicles (EVs) with an estimated addition of over one million vehicles in 2019 alone, continuing to represent more than 50% of the global market for EVs.

What Actis is doing

Actis has been a pioneer in investing in these sectors. Starting in 2005 with our investment in Suntech, then one of the world’s largest solar panel manufacturers, Actis extended its decarbonisation focus to other sectors within its China private equity investments. For example, in the consumer sector, the biscuit brand Jiashili closely monitors and discloses in its annual ESG report its greenhouse gas discharge.

Jiashili cut its discharge by 36% in 2018 compared to 2017, partly due to a switch from natural gas to electricity to power its machinery. In the industrial sector, the fabric company RGB has a dedicated social responsibility team, led by its Chairman himself. In 2017, RGB upgraded its heating facilities to be fuelled by natural gas and electricity rather than coal. Its environmental related investment typically accounts for more than 15% of its total capital expenditure.

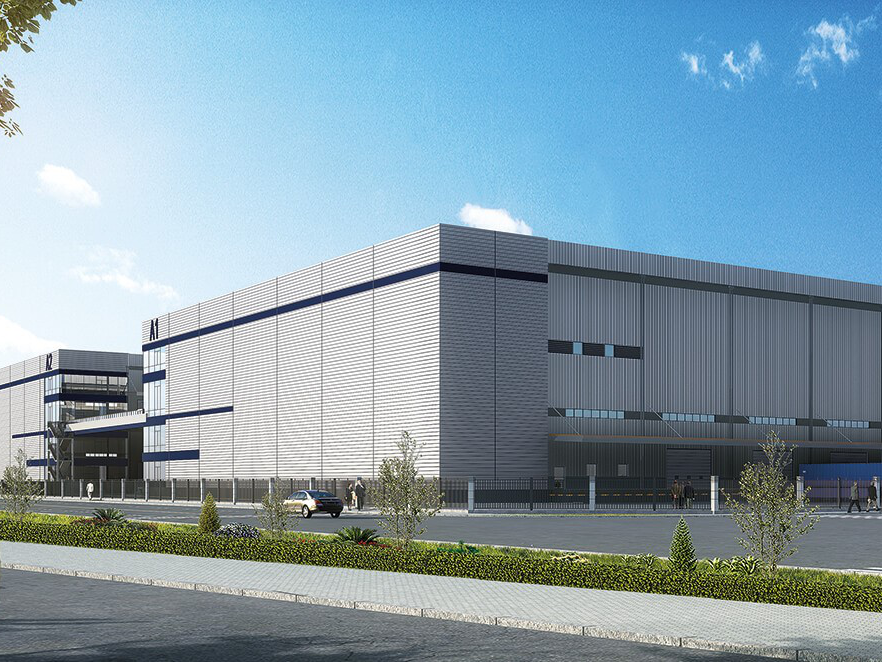

Turning to the Chinese real estate investment market, Actis believes recognition of our responsibility to climate change has always been important to our business.

We seek to develop ‘green by design’ buildings and to increase efficiencies during the development and operation stages of projects. For example, in our logistics development project, Isen, LED lighting is designed and installed instead of traditional T5 lighting.

Furthermore, reclaimed water systems are designed for the outdoor landscape irrigation system and the toilet flushing system. A power transformer station has been situated in between two logistic warehouses in order to provide a relatively shorter power cable distance supply to the two warehouses to reduce the voltage loss.

The Actis team is making every effort to have sustainable construction and green building design, to minimise ne